Barbour Stockwell Crack Detect – CD1

Leave a CommentA Research and Development program or the Qualification of a new rotor design often incorporates Low Cycle Fatigue testing as part of the process. These LCF tests involve cycling the test rotor between two or more speeds many thousands of times; frequently at temperatures to match the in-service environment.

During such testing, the ability to detect the initiation of a crack is immensely valuable. You do not want the first manifestation of a crack to be a burst of the rotor. A burst will generally result in damage to the fracture surfaces adding an extra degree of difficulty to any forensic analyses. On top of that, a rotor burst will necessitate a somewhat costly and time consuming to repair to the test facility.

In the past, frequent inspections such as fluorescent penetrant or magnetic particle were scheduled during the test program to minimize the possibility of a burst. This, of course, added considerably to the duration of the test. So much better to be able to identify a crack at its inception and monitor its progress in real-time during the test.

Barbour Stockwell has developed a crack detect system with proven technology that has shown to be the most effective means for detecting cracks while Spin Testing – boasting a greater than 90% detection rate.

- The technology has demonstrated the ability of measuring cracks as small as 100 µM.

- It can also monitor crack growth during Low Cycle Fatigue Testing.

- The CD1 System has automated shutdown capabilities, superior digital filtering, and synchronous vibration signal isolation to eliminate harmonic content.

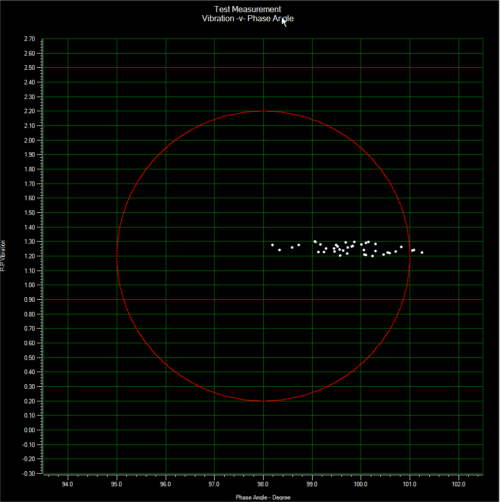

Figure 1 BSI Demonstration Test Article – Crack Initiation